LONG PRODUCTS

Bar and wire

rolling mills

CEA Group manufactures bar and wire rod trains for bar and wire rolling mills for the production of coils.

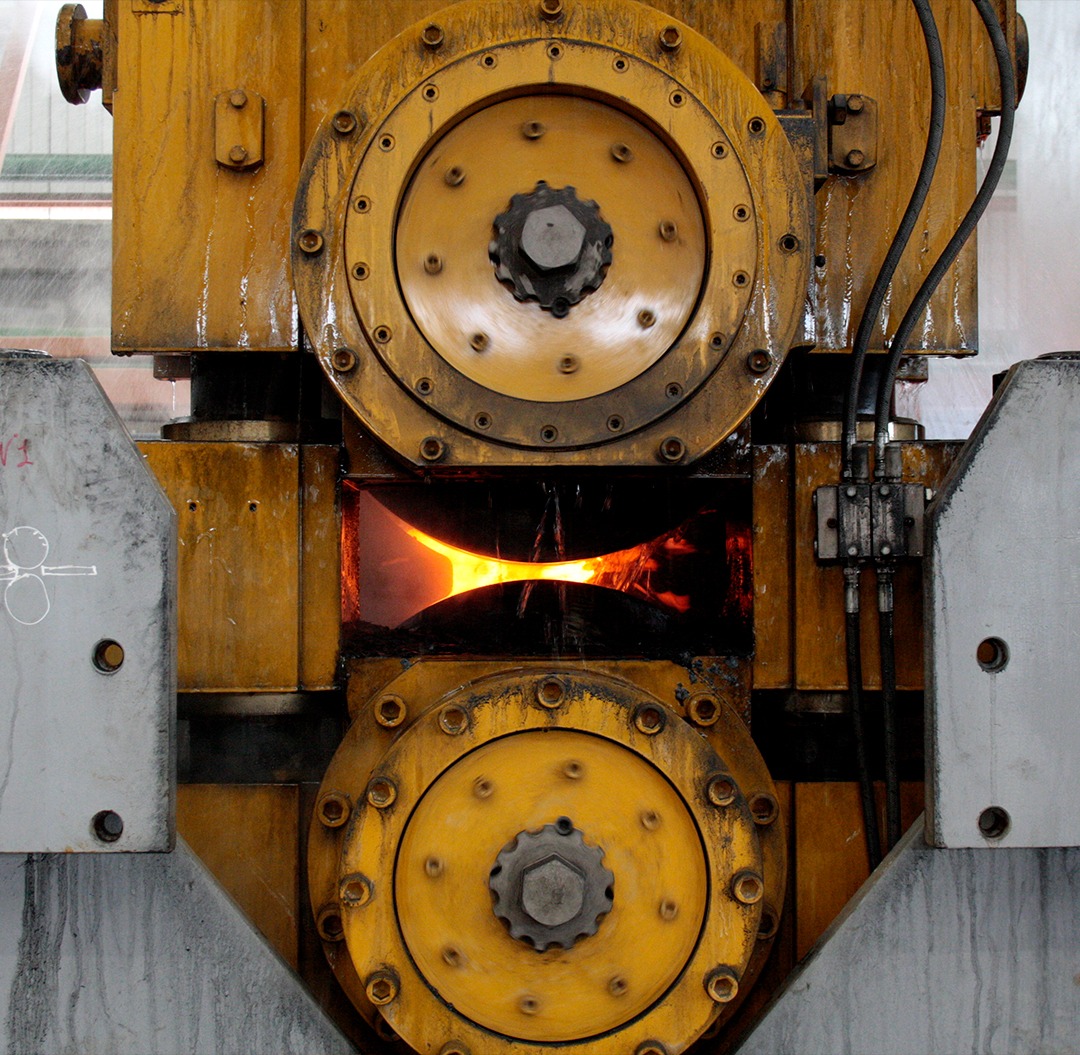

The rolling mill is composed of a series of rollers that progressively press a semi-finished product, giving it the desired shape and dimension. The rollers can have several shapes and dimension: cylindrical for the production of shaped items, for the production of various shape objects (for example smooth or ribbed rounds, H, U, I beams, or rails for railway tracks, etc. ).

Rolling is carried out hot with a bar exit temperature of around 1100 C° , subsequently controlled in the rolling mill designed with the latest generation technologies, ensuring a fine and homogeneous grain structure. The calibrating finishing block for the production of wire rod allows to laminate rolls with narrow dimensional tolerances.

CEA Group manufactures

long rolling mills with the following features:

Bar Mill

Plant consisting of eighteen reduction steps, which has a heat treatment in line with which, thanks to precise management of the parameters regarding flow rates and pressures of water flows, continuously treated and recycled, steels with mechanical properties conforming to the most varied are produced regulations.

Downstream of the hot process, the output in bars rests on a large cooling plate in calm air where, with the automatic advancement and rotation of the same, it is possible to obtain guarantees for a good straightness of the product and high homogeneity of the mechanical characteristics.

The bars are then cut to size with a mechanized system and delivered to the weighing station and automatic packaging in bundles with lengths ranging from 6 to 18 meters.

- Mobile hearth heating furnace of the latest generation

- 28 rolling stands

- Production of bars in the range of Ø 8mm – 65 mm

- Bars cooling plate

Wire Rod Mill

This is a plant with twenty-eight continuous reduction steps, with a series of heat treatments, all sized to produce smooth and ribbed laminates at very high finishing speeds to meet metallurgical needs with adequate microstructures.

At the end of the aforementioned plant, the laminate wound in coils is collected by gravity in hanks supported by perches and sent to the automated pressing and binding stations.

The packaging is in linked formats on 4 positions, for the unwinding of which it is possible to proceed both vertically and horizontally, but always in an axial direction.

The products of the wire rod mill are:

- Production Smooth or hot-ribbed rolls in a range of Ø 5.5 – 16.5 mm with output speed at 110 m / s with product 5.5, in 2,000 kg skeins.

- Controlled Stelmor cooling in the Ø 5.5 – 16.5 mm range