STEEL PRODUCTION

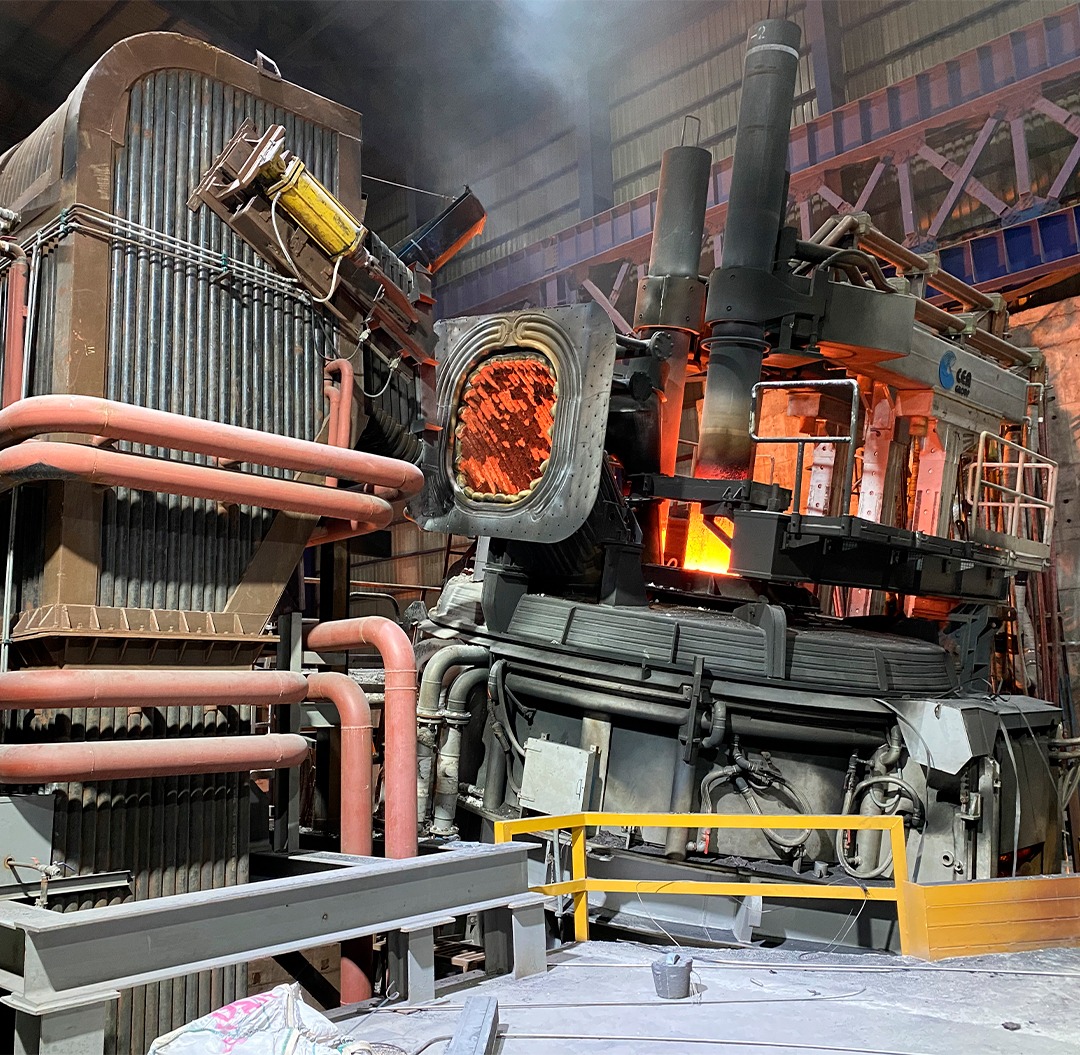

Electric Arc Furnace (EAF)

CEA Group deals with the complete mechanical and hydraulic construction of the Electric Arc Furnace (EAF) according to the performance required by the customer.

Thanks to our electrical automation panels, the furnace is monitored and controlled in all its parts, hardware and software interlocks manage the safety of the operators thanks to the temperature monitoring trends. The melting point is controlled through a PID resulting from years of experience thanks to the DRS CEA Digital Regulation System.

The CEA Fusion Control, installed on an additional supervisor, manages the merger profiles in a totally automatic way and monitors

STEEL PRODUCTION

Ladle Funace

(LF/LRF)

CEA Group deals with the complete mechanical and hydraulic construction of the Ladle Furnace (LF / LRF) according to the performance requested by the customer.

The experience and logic installed on the Electric Furnace Automation electrical panels is transferred to the Ladle Furnace.

The melting point is controlled through a PID resulting from years of experience thanks to the DRS CEA Digital Regulation System.

The CEA Heating Control, installed on an additional supervisor, manages the Heating Profiles and monitors, with continuous additions, the power absorbed by the transformer. The system is designed to optimize the performance of the Ladle Furnace which has the same energy saving needs as the Arc Furnace.

STEEL PRODUCTION

Degassing plant (VD)

The steel degassing is a qualitative treatment of great importance for those who produce quality steels. CEA Group manages the degassing process with its automation electrical panels with the logic of vacuum stage pumps, a system adopted internationally by the major producers of special steels.

Our collaboration with the manufacturers of degassing pumps and our experiences in the commissioning phases have led us to the construction of dimensionally versatile power panels according to the customers’ needs.

The VD-HMI CEA process supervisor is designed for an immediate interface between the operator and the system and careful control of the vacuum measurements inside the vessel which certify the quality of the treatment carried out.

STEEL PRODUCTION

Dedusting sysyem (DDS)

The dust extraction system is managed with an automation electrical panel and several Remote IOs located in strategic points. The interface with the chimney fan motors varies according to whether they are DC motor drives or AC motor inverters.

The DDP-HMI CEA process supervisor monitors and parameterizes the plant. Sometimes this supervisor is integrated into the EAF-HMI CEA Group project to facilitate the consultation of the pages by the operators in case of anomalies.

ECS CEA: an application designed to detect the concentration of dust exiting the chimney and the flow rate of the fumes themselves thanks to the connection of special probes.

STEEL PRODUCTION

Water treatment plant (WTP)

The water treatment plant is managed with automation electrical panels. Inside, the commissioning of the hydraulic pumps can be individually sectioned from the rest of the panel in order to facilitate their electrical maintenance without ever having to stop the circulation of water.

The process supervisor WTP-HMI CEA monitors and parameterizes the system with regard to the levels of the tanks, the operating and stand-by cycles of the pumps, the washing cycles of softeners and sand filters, the flow rates and pressure in the pipes with the relative alarm set-points and so on. Sometimes this supervisor is integrated into the EAF-HMI CEA project to facilitate the consultation of the pages by the operators in case of anomalies.