flat products

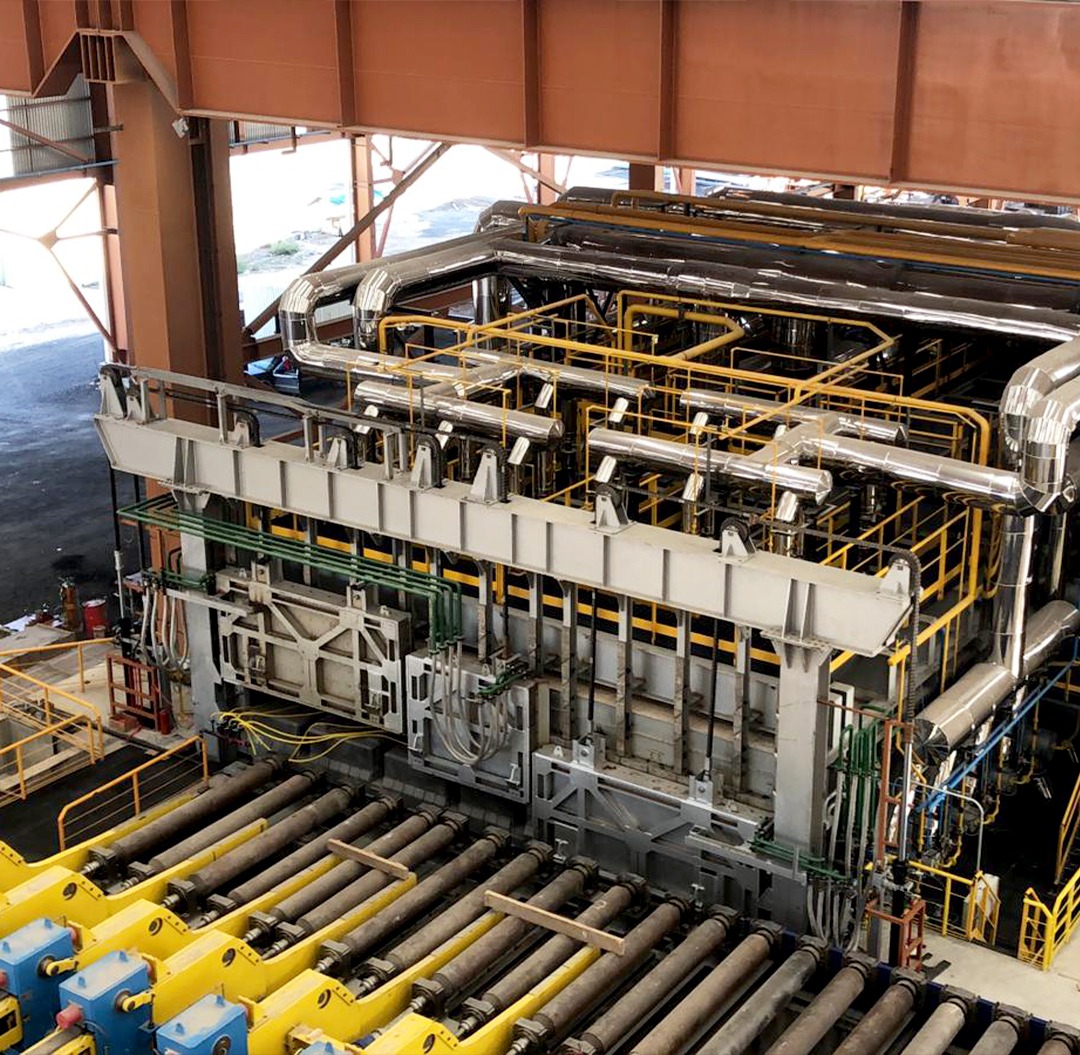

Reheating furnace

CEA Group designs, builds and installs furnaces with upper and lower heating, to be inserted in the rolling lines for heating slabs, blooms at the appropriate temperature (1,100 / 1,250 C°) for the subsequent rolling process.

The continuous passage furnace with active pit consists of: walls, vault, pit, fixed beams (cooled and lined with refractory) and “skids”, regenerative burners (placed both above and below the load).

The unloading system can be front or side, depending on the layout of the plant. Compared to the pusher furnace with unilateral heating, this type of system allows shorter furnace lengths.

° °Internal width: 10.100 mm

Useful length: 25.500 mm

Total installed power: 53,600,000 kcal / h (58,1 MW)

Number of burners installed: 60 pcs.

Discharge temperature of the slab: 1,250 C°

Consumption: 285,000 kcal / (ton loaded)

considering the 100% insulation of the pads with combustion air preheated to 450 C° according to the German VDEH standards

Nr. 7 Independent units for adjusting the combustion air / natural gas ratio

Nr. 7 Independent units for temperature regulation

flat products

Flat rolling mills

CEA Group manufactures flat rolling mills for the production of relatively thick flat metal products with a rolled or heat treated steel, with a minimum thickness of at least 5 mm and a minimum width of at least 1,200 mm.

Sheet steel is a widely used product. It normally falls into the categories of carbon steel, high strength and low alloy steel (HSLA) and alloy steel.

CEA Group is able to manufacture flat rolling mills with the following characteristics:

Initial cravings:

- Thickness from: 200 – 350 mm

- Minimum width: 1,500 mm

- Length of slab calculated on the basis of the final product requested with a mathematical model from: 1,500 – 3,500 mm

Finished sheet with features

- Thickness: 9.52 – 101.4 mm

- Width: 1500 – 3048 mm

- Length: up to 18.000 mm

The CEA Group service includes numerous activities to support customers’ needs:

- Basic and detailed design

- Systems engineering

- Mechanical production

- Production of electrical hardware

- Software development and testing

- Installation and testing

- Commissioning and tuning

- Technical assistance

- Training